-

RF Series

-

Chassis & Controller

-

Non-RF Series

-

CW Power Amplifier

-

Optional Pulse Power Amplifier

-

Power Amplifier Module

-

EMC200V/m Series Amplifier

-

Low-Earth Orbit (LEO) Satellite

Communication Simulation System

-

Satellite TT&C

(Telemetry, Tracking & Control) Testing

-

Antenna Testing Solutions

-

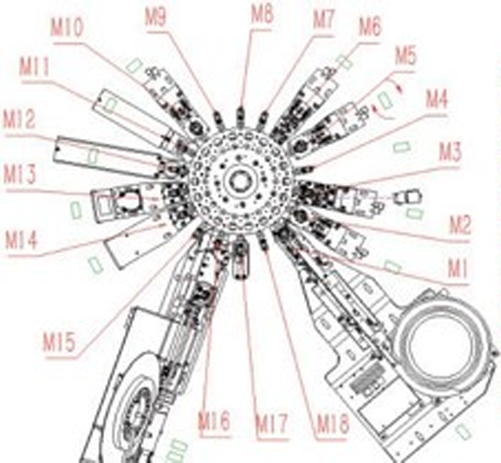

All-in-one Sorting and Testing System

-

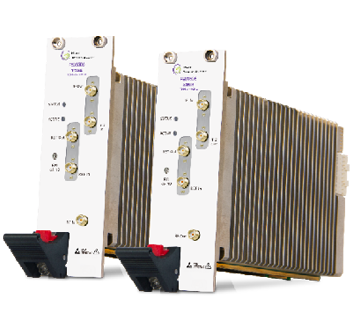

High-Speed Cable Test System

6GHz Up/Down Converter

FEU3506/FED3506

26.5GHz Down Converter

FED3526

43GHz Up/Down Converter

FEU3543/FED3543

RF Signal Generator

RSG3745

Vector Signal Transceiver

SGR3006/3008

Vector Network Analyzer

SNA3308/SNA3308U

High-Performance PXIe Chassis

PXC1192T

RF Switch

SSM3608

Chassis

PXC1080

Chassis

PXC1180

Data Storage Module

SDA Serie

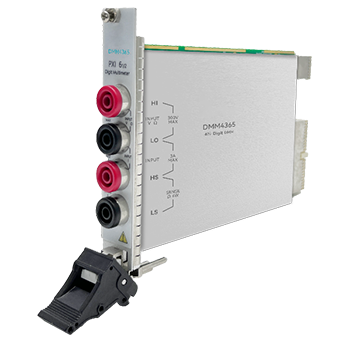

Digital Multi-Meter

DMM4365

Oscilloscope / Digitizer

SDS4025

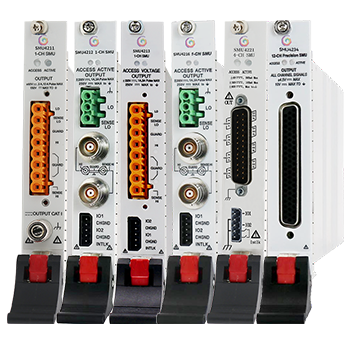

Source Measure Unit

SMU Series

Bus Transceiver Module

ARINC429

Bus Communication Card

MIL-1394B

Bus Communication Card

MIL-STD-1553B

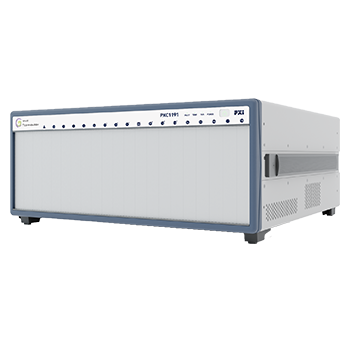

Chassis

PXC1191

Controller

PXC2080

Controller

PXC2190

9kHz - 6GHz Series

.png)

2 - 26.5GHz Series

.png)

6 - 18GHz Series

.png)

18 - 40GHz Series

.png)

40GHz and above series

Optional Pulse Power Amplifier

Power Amplifier Module

EMC200V/m Series Amplifier